In today’s highly competitive business landscape, maximizing efficiency is critical. From the factory floor to the customer’s door and throughout the supply chain, ensuring your products arrive on time and as expected is essential to customer retention—and profitability.

IoT is a major catalyst in this effort, as it provides ways for the enterprise to monitor everything from machine function to logistics. Such visibility enables companies to make just-in-time business decisions, streamline processes, and delight customers at scale. While this might seem like a complicated undertaking, the technology is highly accessible and cost-effective, opening new avenues for risk reduction and a greater level of control over just about every process.

Why Temp Sensors?

Wireless temp sensors are a component of industrial IoT that can be leveraged in several ways to achieve maximum profitability and reduce the risk of loss.

A few of the most common use cases for temp sensors include:

- Food Manufacturing and Packaging

- Restaurants

- Grocery Stores

- Residential, Commercial, and Institutional Buildings

- Supply Chain And Logistics

- Factories

- Warehousing

- Agriculture

- Natural Resources

- Manufacturing

- Oil and Gas

- Water Services

- Chemical Processes

With the ability to monitor temperature in these settings, operators avoid machine breakdowns, avert spoilage, and minimize risk caused by temperature fluctuations.

Refrigeration Temperature Monitoring

In the food and restaurant industry, accurate temp monitoring is vital. The federal government issues temperature guidelines for food storage and safety, which is overseen by health and safety inspectors. Fines for non-compliance can be steep and organizations face forced closure for repeated infractions.

Besides, there is public safety to consider. According to the Centers for Disease Control (CDC), food spoilage causes illness in 48 million people every year in the United States. Though this is a number that combines instances stemming from restaurants as well as the groceries we purchase from a store, it is clear that adequate temperature control has a part to play in loss mitigation.

However, human monitoring is often unreliable. Even the most diligent workers overlook temperature details at times, and for a high-cost product, that translates to significant potential loss.

Wireless temp sensors allow operators to monitor conditions remotely. Sensors issue real-time alerts, notifying stakeholders of temperature anomalies in time to avert spoilage.

Restaurants that have a lot of money tied up in wine inventory can also benefit from remote temp sensors. When storing high-value wines, both temperature and humidity must remain consistent, or degradation can happen. Sudden temperature spikes can quickly render some wines undrinkable, leading to unrecoverable losses and an increase in the cost of doing business.

In an industry with a notoriously tight margin, every dollar counts, and temp sensors are an excellent way for the food and beverage industry to preserve profits, maintain product quality, and satisfy health and safety compliance mandates.

Industrial Use Cases

In industrial settings, temp sensors play various roles. They are a component of machine function optimization. They also help monitor the facility’s ambient temperature, which can be a highly critical concern, depending on the industry and product.

Common industrial use cases for temp sensors include:

- Refrigerators. Maintain an optimal storage temperature range and prevent freezing.

- Cold Storage. Maintaining a consistent temperature is essential for many commodities.

- Boilers. Sensors will indicate leaks and insulation failure.

- HVAC. Temp sensors help operators monitor systems for leaks, breakage, and energy loss.

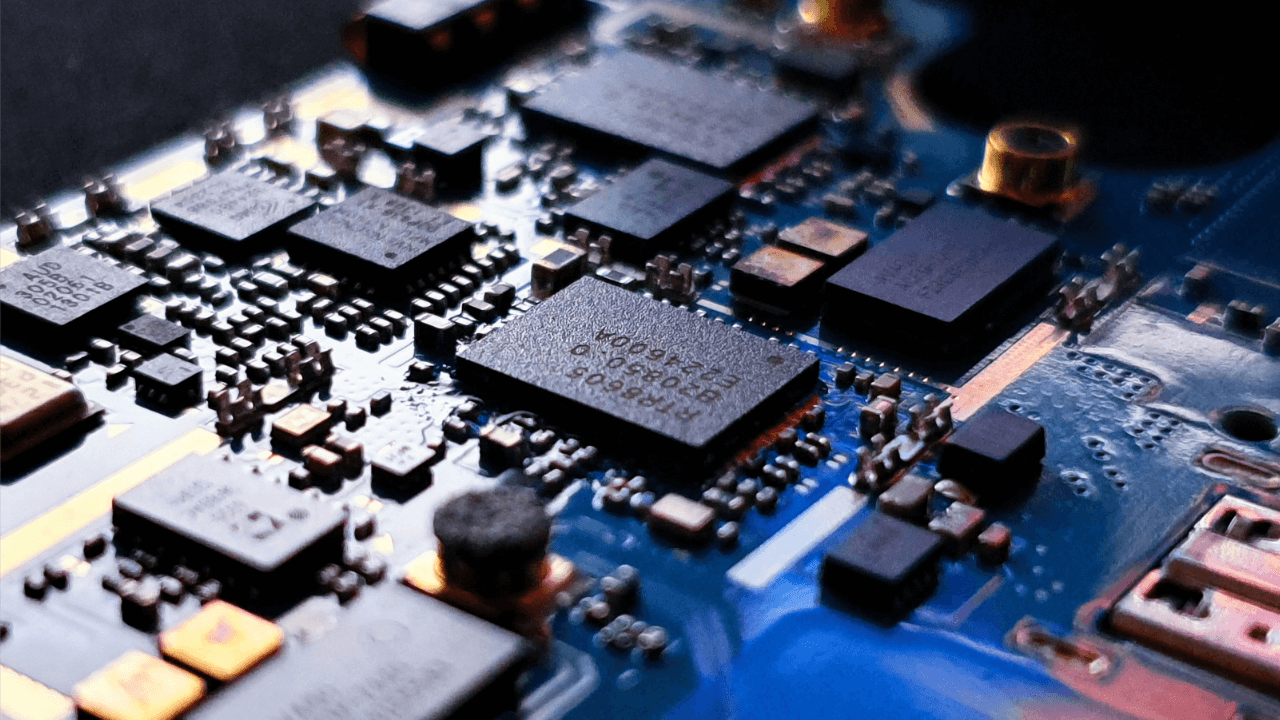

- Electrical. Heat spikes in electrical systems are a precursor to significant safety risks.

- IT. Computers and servers will malfunction and fail if overheated.

- Solar Energy. Reduced solar function affects power grids and all connected clients.

Maintaining Optimal Machine Function in Manufacturing

In manufacturing, temperature fluctuations are an indicator of machine overload, power surges, or complete breakdowns – any of which have the potential to disrupt the supply chain, erode profit margins, and cause a ripple effect of customer discontent.

Monitoring temperatures at the machine level helps factory operators save in many ways:

- Optimize Management Time. Real-time alerts allow foremen to respond immediately, reducing time spent on manual monitoring and allowing them to focus on higher-value tasks.

- Improve Worker Safety. Taking machines offline before they malfunction increases worker safety.

- Reduce Maintenance Costs. Temp sensors reduce unnecessary maintenance calls.

- Maximize Uptime. When machines are functioning as they should, production levels soar. By some estimates, machine downtime costs manufacturers in the realm of $50 billion each year in the United States, and almost half of that is due to machine failure.

Smart Building Applications

Today’s most efficient buildings rely on IoT sensors for a range of functions, and temperature control is among the top concerns. With the ability to monitor and control the temperature in individual spaces—like apartments, offices, hospitals, and even jail cells—it is possible to reduce heating and cooling costs and optimize the building’s energy usage.

Companies that manage massive complexes, like shopping malls, universities, data centers, storage facilities, or any organization that maintains multiple buildings derive a distinct advantage from temp sensors. With a remotely-monitored solution, it is easy to centralize and simplify oversight and control of everything from comfort to safety, even if the facilities are located on the other side of the world.

With the ability to detect temperature fluctuations and system failure, companies can reduce costs related to daily operations, system failure, inefficient machine function, maintenance, repair, occupant comfort and safety, and loss due to temperature variation.

How Radio Bridge, A MultiTech Brand, Helps

Radio Bridge offers a range of wireless temperature sensors to suit just about every commercial and industrial need. Our sensors are suitable for indoor and outdoor use, and the wireless signal can even penetrate through walls and floors.

Alerts can be configured to trigger when the temperature rises or falls below configured thresholds and sends a notification to your managers in real-time, based on your settings. Best of all, managing and monitoring your temp sensors is easy as your data is centralized into a single pane of glass, optimizing your time and helping you maximize value throughout the organization.

If you would like to learn more about wireless temp sensors and how they can help you, reach out today. We’d love to show you what’s possible.