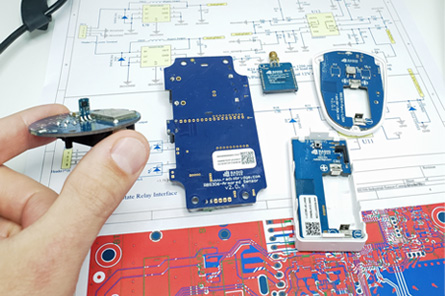

For a combined device (multiple sensor types in one), we typically recommend using multiple devices from our standard product portfolio for initial testing, and then a commitment on MOQ (minimum order quantity) will often be sufficient for us to move forward with the combined device design.

Minor changes to the firmware are often fairly simple, and again, a small commitment for a minimum order quantity is often all that is required. This may include custom payload structures, custom data conversions, custom reporting requirements, or countless other tweaks necessary for seamless integration into the end customer’s system.

Modifying the PCB hardware can also be a straightforward task, however there may be additional costs for prototyping, test fixture development, FCC certification, etc. In this case there will usually be a small NRE (non-recurring engineering cost) to cover these expenses.

Custom Wireless Sensor Design

Custom Wireless Sensor Design