At Radio Bridge, a MultiTech brand, we’ve developed a sensor that enables industrial operators and manufacturers to connect any off-the-shelf 4-20mA device to LoRaWAN® networks.

Our 4-20mA current loop sensor serves as a bridge between wireless sensors and the leading low-power wide-area network (LPWAN) standard. Using this device, operators can easily monitor onsite industrial processes and signals. They can measure different types of outputs and send data directly to the cloud for processing.

4-20mA sensors alleviate many of the challenges associated with deploying industrial Internet of Things (IoT) applications. In this post, we highlight the benefits of this particular type of device and share examples of how they can be used in practice.

Overview of 4-20mA Current Loops

The 4-20mA loop standard has become the status quo in the world of process control.

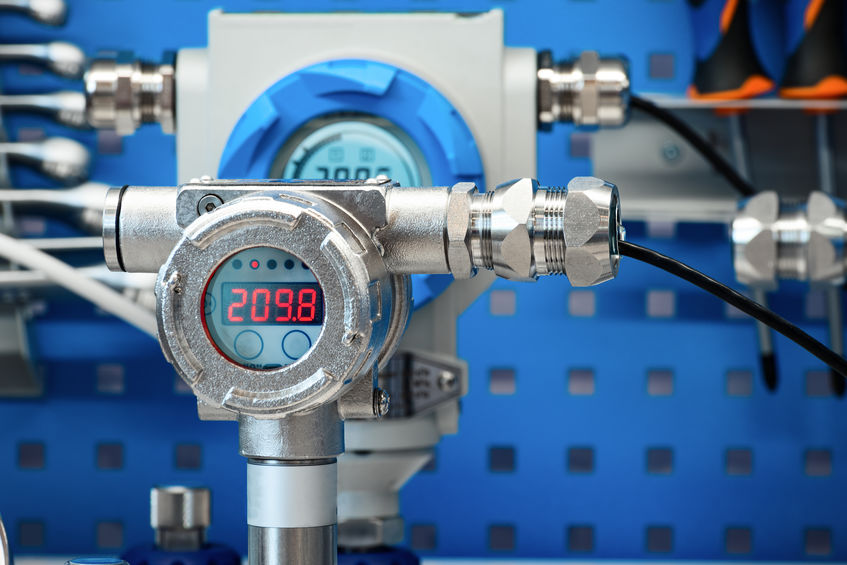

4-20mA current loops allow us to collect information about certain process variables efficiently. Today’s 4-20mA sensors can track a variety of variables, including temperature, pressure, humidity, and water levels. These sensors connect to transmitters, which help convert process inputs into electrical signals between 4 and 20 milliamps. Electrical signals pass through current loops and are ultimately sent for processing so that operators can evaluate the conditions of different industrial applications.

4-20mA sensor data readings are relatively simple to interpret. Values on the low end of the electrical range correspond to low variable values. High current values correspond to high variable values.

For example, a 4-20mA current loop configured to measure tank water levels might assign an empty tank a value of 4 milliamps and a full tank a value of 20 milliamps. In this scenario, an electrical current of 12 milliamps would imply the water tank is half full.

In the temperature domain, operators could assign 4 milliamps to 0 degrees Celsius and 20 milliamps to 100 degrees Celsius. 10 milliamps would translate to 37.5 degrees Celsius. Readings below or above these thresholds would signal to operators that something is not right in the system.

The Pros and Cons of 4-20mA Current Loops

4-20mA current loops offer several advantages for process control applications.

First, the 4-20mA current loop is the dominating standard across most industries. Consequently, 4-20mA sensors tend to work well in many settings.

4-20mA current loops are also cost-effective and simple to configure. They do not require much wiring and 4-20mA current loops can cover long distances. Electrical current also does not degrade as much as other types of control signals, making it a safe option for data transmission.

With 4-20mA current loops, operators can automate data collection for critical processes and stay on top of their industrial applications without much manual effort. Additionally, thanks to advances in edge computing and LPWAN technology, we can also process 4-20mA sensor readings offsite in the cloud.

This is where Radio Bridge comes in.

Radio Bridge’s 4-20mA Current Loop Sensor

At Radio Bridge, we offer several types of wireless extensions (or “radio bridges”) that enable operators to connect third-party sensors to LoRaWAN networks.

Our 4-20mA current loop sensor can connect to off-the-shelf 4-20mA devices and transmit readings directly to networks supported by the leading LPWAN standard, LoRaWAN. As a result, operators can essentially turn any low-cost 4-20mA sensor into a LoRaWAN sensor.

——————————————————————————–

You can turn any low-cost 4-20mA sensor into a LoRaWAN sensor

——————————————————————————–

For example, if you wanted to incorporate a LoRaWAN differential pressure transmitter into your network, you would only need to purchase a generic 4-20mA-enabled device. Our 4-20mA current loop sensor could send your pressure sensor readings up to several miles directly to the cloud supported by your LoRaWAN network.

With a general purpose pressure transmitter and our 4-20mA loop sensor, you could automate pressure readings in power stations, boiler rooms, and clean rooms. You could also install these devices in industrial vacuum cleaners and air conditioning units, thereby converting them into LoRaWAN sensors.

You could also purchase a low-cost temperature sensor directly from any major retailer and quickly set it up to help monitor environmental conditions in your industrial plants. Should any readings fall above or below your defined thresholds, our sensor would alert your operators. By doing so, you avoid buying an expensive LoRaWAN temperature or humidity sensor without sacrificing the overarching functionality.

Our 4-20mA loop sensor also works with different types of liquid sensors. Connect submersible tank level sensors directly to your LoRaWAN networks and capture depth readings in storage tanks or fuel containers. Deploy 4-20mA water presence sensors anywhere you have sensitive machinery or equipment that should not get wet. Place water presence rope sensors along data rooms or storage centers to prevent property damage from flooding. If water is detected, these sensors will send a signal to our 4-20mA loop sensor. Signals are then forwarded to your LoRaWAN network and personnel.

Vibration sensors, inclinometers, and accelerometers can all connect to LoRaWAN networks as well through our 4-20mA current loop sensor. All of these devices help industrial operators catch equipment malfunctions early. For example, users can configure inclinometers to send alerts when oriented at certain angles, indicating equipment may be at risk of tipping over. Vibration sensors can enhance industrial equipment safety systems that provide early failure detection.

The 4-20mA current loop can also transform wireless air quality sensors into LoRaWAN devices. Connect wireless ammonia sensors, carbon monoxide sensors, methane sensors, and benzene sensors to our 4-20mA loop to establish air quality safeguards throughout your facilities. You can also integrate ambient light sensors into your networks to detect light intensity in factories, warehouses, and buildings in which sensitive items are stored.

With Radio Bridge’s 4-20mA current loop sensor, the IoT possibilities are endless for industrial operators.

Processing in the Cloud

By connecting off-the-shelf devices to LoRaWAN networks through our current loop sensor, organizations can process industrial control signals in the most efficient way possible.

Operators don’t have to purchase high-power devices that can process control inputs natively. Instead, this information can be transferred securely to the cloud. For those who manage hundreds or thousands of sensors across their IoT networks, this translates to much lower setup and ongoing costs.

Our 4-20mA current loop device replaces LoRaWAN-specific sensors and allows you to achieve the same functionality in a far more cost-effective manner. You can take advantage of off-the-shelf products and automate data collection for their most important processes.

Whether operators need to guard against liquid leaks, temperature abnormalities, harmful gases, or other environmental issues, Radio Bridge’s 4-20mA sensor is the solution.

Summary of Sensor Applications

- LoRaWAN air quality sensor

- LoRaWAN batch controllers

- LoRaWAN calibrator

- LoRaWAN differential pressure sensor

- LoRaWAN flow rate sensor

- LoRaWAN high current sensor

- LoRaWAN high voltage sensor

- LoRaWAN level sensor

- LoRaWAN pump control meter

- LoRaWAN signal generator

- LoRaWAN speed sensor

- LoRaWAN strain sensor

- LoRaWAN temperature sensor

- LoRaWAN water level sensor

- LoRaWAN weight sensor

- LoRaWAN wind speed sensor